How to Properly Maintain your Bandsaw Blade?

There are four key points to be aware of when maintaining your bandsaw blade:

Planned maintenance

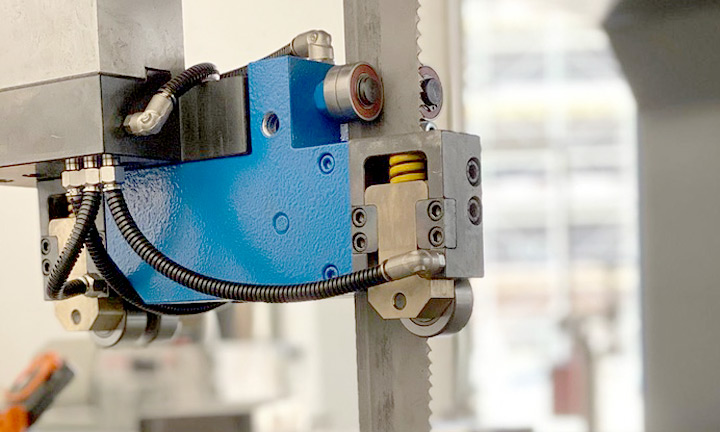

All workshop equipment requires planned routine maintenance to maximise top blade performance. A blade will last much longer if you have the whole machine serviced regularly. By making sure that everything is running properly on your saw – bearings, tensioners, guides etc – will help your blade keep its alignment and maintain the correct tension.

You can help keep your bandsaw in the best condition by following a daily cleaning and lubricating routine, including lightly oiling the bearings where possible, and using an airline to blow away any swarf that has built up in the blade and mechanism. A lot of the general maintenance you will be able to do yourself however, we would recommend that your bearing guides should be replaced and serviced by a qualified machinery engineer.

Running-in procedure

It is important to recognise that when you fit a new blade that it will need to be run in. Running in (sometimes called bedding in) your new blade is essential to prevent common issues such as broken teeth and premature blade wear. To do this, we recommend running your saw at around half speed and at a reduced rate – a low as a third – feed force to lower the initial stresses experienced by the blade. This lowered running speed helps take the extra-sharp edges off the blade by allowing it to bed into the material slowly assuring a much longer service life.

Check your tension

When a blade is subject to a lot of work, it will heat up and expand, causing tensioners to take up the slack. Once the work is stopped, there is a chance of blade damage through micro-cracking if the tension is then not taken off the blade. We recommend that after a long job, where the blade has got hot loosen the blade tension back a few turns to help prevent this.

Coolant is key

While different metals may require different coolants to ensure correct operation, it goes without saying that some kind of lubricant absolutely must be used. Coolant both lubricates the cutting area and removes heat from the blade all over. If you do have a reservoir and oil-pump system, you should have the oil replaced at regular service intervals, and any filtering cleaned out. The Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes, and although in most cases you mix the coolant with water, you must never use water only as this can lead to severe problems such as bacteria growth, corrosion and poor surface finish.

By carrying out these simple but effective pieces of maintenance, you can add years to the machine and maximise your blade life and performance.